The Company

Topics

Contacts

intralogistics

From development to production, from stock rotation to delivery: the deadlines for satisfying customer requests are increasingly tight. Today, no company can allow its warehouse to become a bottleneck due to the inability to make the management of activities and the storage of goods fluid and flexible.

This is also true for the paper, tissue and nonwoven industries, where intralogistics represents a strategic aspect both within the production process and in the warehouse arrangement.

Let’s consider companies like Amazon or FedEX, which manage countless shipments, or like Tesla, for which logistics is a fundamental factor: all have made the optimization of material handling one of their strengths and this has helped to increase their profitability more than 30 times compared to the reference market.

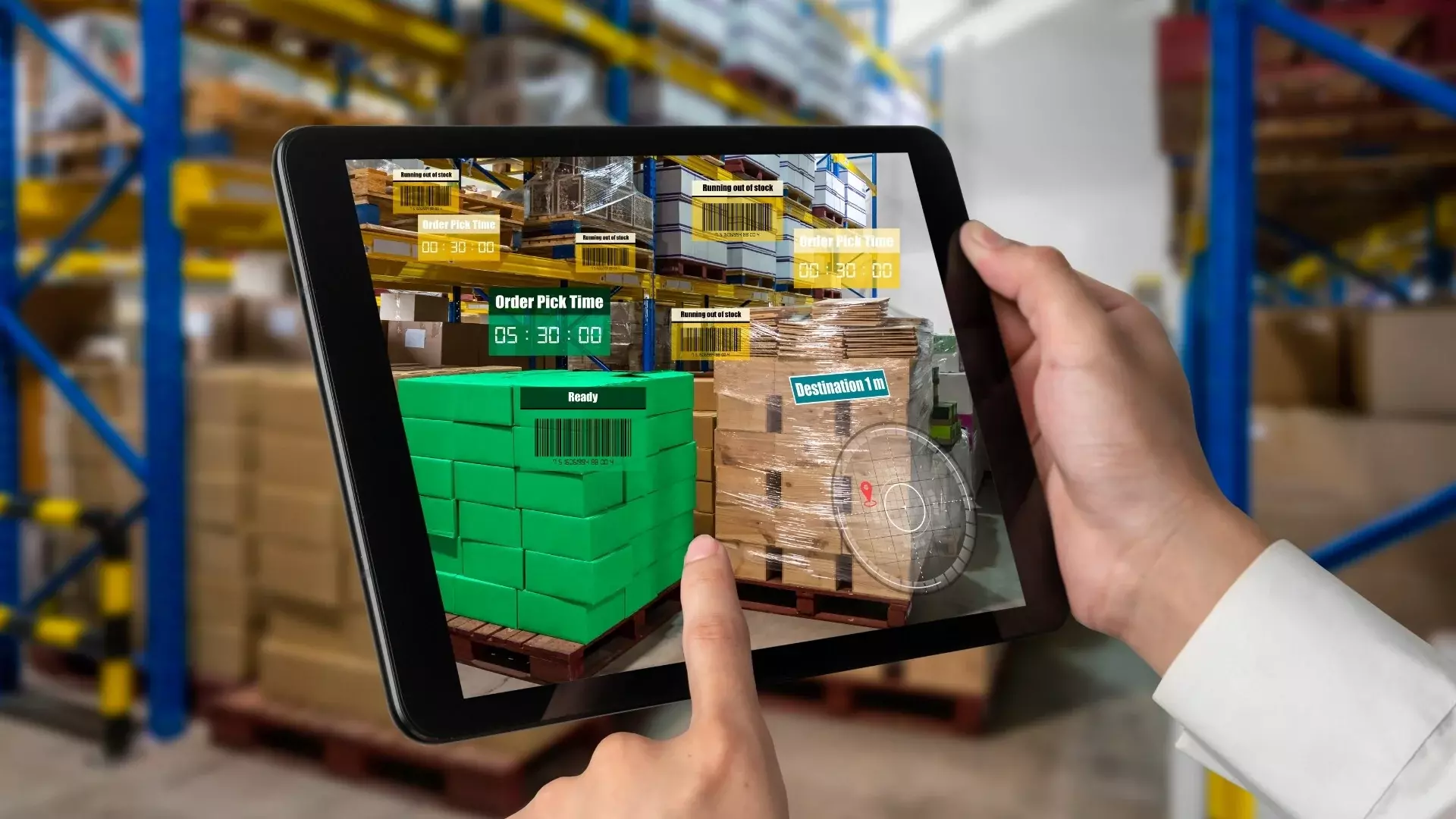

Today, in fact, an organization must be flexible and open to change but also extremely precise and punctual, given the high expectations of customers and their low tolerance for errors. It is therefore not surprising that a recent analysis has shown that 96% of companies have already automated the warehouse or intend to do so in a relatively short time.

Anyone who has had the opportunity to make purchases in a warehouse like that of Ikea knows how long it can take to find the products on the shelves. The same happens in a company warehouse: a combination of factors, including an incorrect arrangement of the goods or the difficulty of identifying their location, means that the time spent searching for products represents about 60% of the total working time.

It is an activity with no added value, which heavily affects productivity and costs. However, thanks to the automation of material handling processes, this waste of time can be reduced by up to about 90%, with a consequent streamlining of production and supply chain management processes.

Intralogistics represents a strategic aspect for any company. Continuing to use a semi-automatic system, even within plants where processes are now fully automated, means nullifying many of the advantages obtained in the production phase.

Automated intralogistics is not a vehicle, product or software, but an integrated system composed of several elements that together contribute to the final purpose.

In fact, automated intralogistics generally includes:

In the case of a warehouse, the vehicles used can be, among others, AGVs (Automated Guided Vehicles), stacker cranes, rail-mounted satellites or pallet shuttles.

Relying on these solutions allows not only to recover lost productivity due to the lower efficiency of manual operations, but also to eliminate the probability of error and the related costs.

Automating your warehouse also means benefiting from 24/7 operations, avoiding the organization of work shifts and allowing staff to spend their time in other activities with higher added value for the company business.

It should not be underestimated that the warehouse is one of the places in the company where the level of safety at work is most often tested. In this sense, automation contributes to considerably limiting accidents during the handling of products, particularly heavy in the case of the paper and nonwoven industry, thus increasing safety for operators.

As mentioned, the use of solutions for the automated management of products in the warehouse allows significant savings on labor costs. However, even greater savings derive from the elimination of costs related to "intangible" elements, for example:

How much do these items weigh on the overall costs of the company? Every business owner can give a different answer to this question, but they sure make a big impact in any organization.

These costs, in addition, they help to determine another fundamental aspect for evaluating the convenience of automated intralogistics compared to manual: the payback period. It is undeniable that the initial investment is more substantial, but by decreasing the intangible costs it is possible to recover the investment much faster. Estimates indicate that the average time is between 18 and 26 months, depending on the configurations implemented.

Companies in the paper and nonwoven industries have to handle large and heavy reels. The challenge in this case is not only to be able to move them easily and to store them in the warehouse making the most of the available space, but also to handle them correctly so as not to damage them and receive a claim due to poor product quality by the end user of the reel itself.

From what has just been said, it is obvious that entrusting reel handling only to operators can be risky both for safety reasons and for possible complaints about the product.

The solution is to resort to automation, entrusting the correct handling of the reels to self-driving vehicles. AGVs can in fact easily manage these types of products, without the risk of damaging them, from the end of the production line to the packaging area, and from this to the loading bay.

The SW system that manages reel handling has a direct connection with the company ERP. This allows you to know the entire history of the reel, from production to shipment to the customer. It is therefore possible to get a complete traceability of the reel to certify the quality of the process and not only of the product.

During reel packaging, up to three distinct labeling processes can be encountered: on the cardboard core of the single reel, on its external surface and on the outside of any bundle of reels requested by the customer.

This allows you to always have all the information relating to the various production and packaging stages. However, it is possible to equip the reel with a richer information kit, thanks to A.Celli's virtual labelling.

Whoever controls the labelling cycle can add a virtual label (resulting from the automation of the workflow) to the physical label. In practice, every time the reel is moved, a set of data relating to each single operation performed is created in real time. The virtual label adds a series of qualitative information to the physical label, which instead provides purely quantitative information. The new data makes it possible to trace the entire reel path in a safe, certified and inviolable way during production, storage (warehouse inventory management) and shipping.

The term blockchain has become synonymous with trust, because it implies the creation of a distributed database that contains information that can be shared over a network, but not modified. In practice, the information is stored in the database as blocks connected to each other in a chronologically consistent manner within a chain, which cannot be deleted or modified without the consent of the entire network. It is thus possible to create a sort of unalterable ledger that allows you to track orders or the movement of goods.

This can also apply to the entire production process of the reel and its management in the warehouse, obtaining an even more "reliable" indication compared to the virtual label when it comes to reel traceability. A.Celli, as a provider of cutting-edge solutions for the handling of products in the warehouse, is planning to be able to trace the production and storage process of the reels also through the blockchain.

A non-automated warehouse is now synonymous with lost productivity. To recover it, A.Celli offers a system for the automation of corporate intralogistics: an ASRS (Automated Storage and Retrieval System) based on quality components, which makes robustness one of its strengths and is able to provide reliable results without requiring, for example, to check several times if a certain reel really reflects the characteristics requested by the customer.

Distinguishing element of the A.Celli offer is the system manager, an inventory management software consisting of 7 modules (order management, vehicle management, traffic management, layout management and others) capable of interfacing directly with the company ERP. A.Celli has focused particularly on this aspect, creating a process automation software able to communicate effectively with all the most popular ERPs.

The result is a system that allows you to improve productivity, carry out accurate product quality control, certify the value chain and reduce costs. In practice, this means being able to quickly provide certification of the receipt of an order received. An effective system for the automation of intralogistics allows the company to invoice today what has been ordered today, since the warehouse can automatically coordinate with the management area and the time that passes between the administrative event and the movement of the AGV is virtually reducible to zero.

Thanks to the use of artificial intelligence, it is possible to carry out analysis in order to act in advance, thus avoiding problems due to processes performed incorrectly.

A.Celli's offer is designed to automate intralogistics operations for any type of plant, with a particular focus on the company's core business: the production and storage of paper and nonwoven rolls.