The Company

Topics

Contacts

soft materials handling

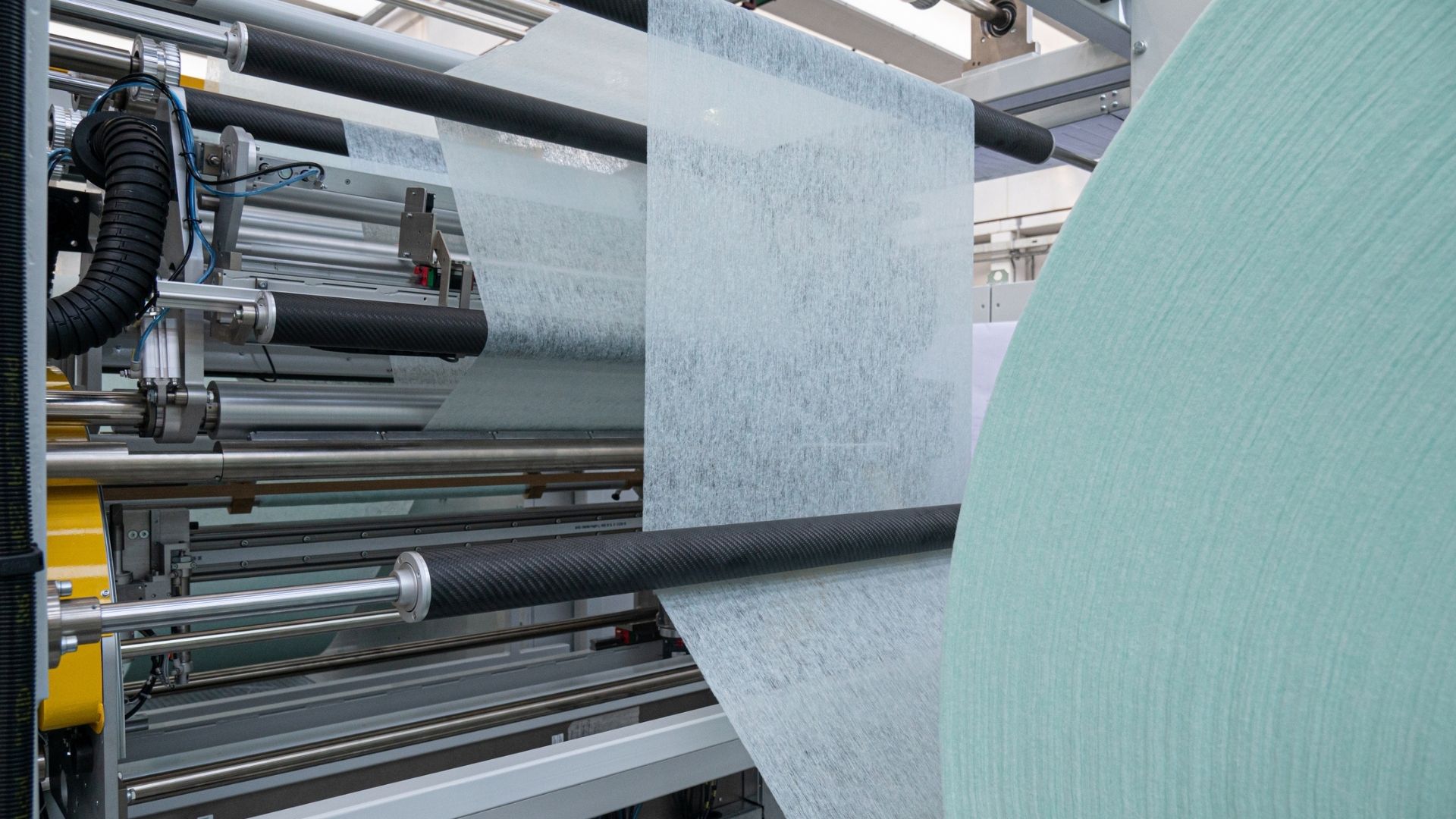

The market for hygienic products sees an increase in demand for nonwovens with high softness and bulkiness. However, it is not enough to obtain these characteristics during the production process: it is also necessary to preserve these qualities even in the so-called end-of-line, i.e. in the rewinding, packaging and handling phases, up to the shipment.

Therefore, it becomes essential to process these materials with solutions specially designed and built to preserve their characteristics. An incorrect or inaccurate rewinding process, for example, can cause an elongation or a crushing of the wound material with consequent substantial loss of the desired characteristics. Furthermore, this same material could benefit from alternative processes to rewinding, depending on the needs of the end customer.

For these reasons A.Celli has developed a series of solutions capable of preserving the softness, bulkiness and high thickness of these materials from the end of the production line to the shipment.

All this is enriched by the consultative approach of our Sales Managers, who are responsible for understanding the precise needs of each customer in order to propose tailor-made solutions for the entire end-of-line.

A.Celli is able to process and manage particularly soft nonwoven materials of any size and diameter. This is thanks both to the technical solutions applied to our winders and rewinders and to a different intermediate process for the preparation of the final product as alternative to the "standard" rewinding itself: the spooling

This process is taken into consideration when the finished reels of soft nonwoven may require processes other than rewinding or when it is more convenient, both from the logistical point of view and for the density of the finished product, if the needs and possibilities of the downstream converter allow it.

In fact, a delicate material such as soft nonwoven runs the risk of not being able to be wound adequately while maintaining its characteristics using the traditional winding process, thus giving rise to excessively bulky reels and with little wound material. It is precisely in cases like this that the spooling process come into play, technologies present in the F-LINE® range which complete the range of A.Celli end-of-line solutions for the management of soft nonwoven materials.

The F-LINE® spooling line allows you to wind particularly soft nonwovens strips, giving birth to a finished reel with an overall width larger than the single strip itself.

A Spooling line ideally includes three sections: unwinding, slitting and actual spooling. Therefore, starting from the mother rolls, we obtain a number of nonwoven strips equal, at most, to the number of spooling heads with which the line is equipped and of a considerably smaller width, which will subsequently be wound around a shaft.

The peculiarity lies in the fact that, during the winding process, the shaft moves transversely thus allowing, with a process ideally similar to the winding of fabric yarns, to obtain finished reels containing a greater number of meters of material than a standard reel, with obvious advantages in terms of reliability in the subsequent converting phase.

Aware of the processing needs of the products dedicated to the hygienic market, particular attention is paid to products like High Loft nonwovens, particularly soft and bulky materials used for top sheet and back sheet applications in diapers, products dedicated to feminine hygiene and adult incontinence products.

For this purpose A.Celli developed a dedicated package for the E-WIND® range which provides for the implementation of a wide range of technological solutions on the various components of the machinery involved, from the unwinder to the slitting unit, up to the rewinder, to best process this nonwoven fabric and preserve its particular characteristics.

A.Celli's modus operandi always provides for a consultative approach that favors working side by side with its customers, giving life to machines with design and construction optimized according to the specificities of the product to be treated.

Furthermore, the analysis in question does not stop at this level but also takes into consideration the needs and assets of the converter. All this is combined with our "one source, one responsibility" philosophy, which allows us to guarantee you perfect management and care of your product at all stages of the end-of-line. Automatic transfer of the product between various lines or within the factory, winding, unwinding, rewinding and packaging, not to mention the automation of intralogistics processes and Industry 4.0 digital solutions: A.Celli is able to offer you all this and much more.

Contact us and you will find trained qualified personnel at your disposal who can help you choose the best solution for your needs. Click on the banner to request a consultation!