[UPDATED ON MAY 2025]

Once the production process is completed, the third phase of our "journey" begins, that is packaging: a fundamental activity to ensure your customers a flawless, high-quality product compliant with market demands.

A packaging process performed incorrectly and without taking into account the specific characteristics of the reels can in fact result in damage or involuntary contamination of the product, a particularly serious event in the case of nonwovens intended for the medical and hygienic market.

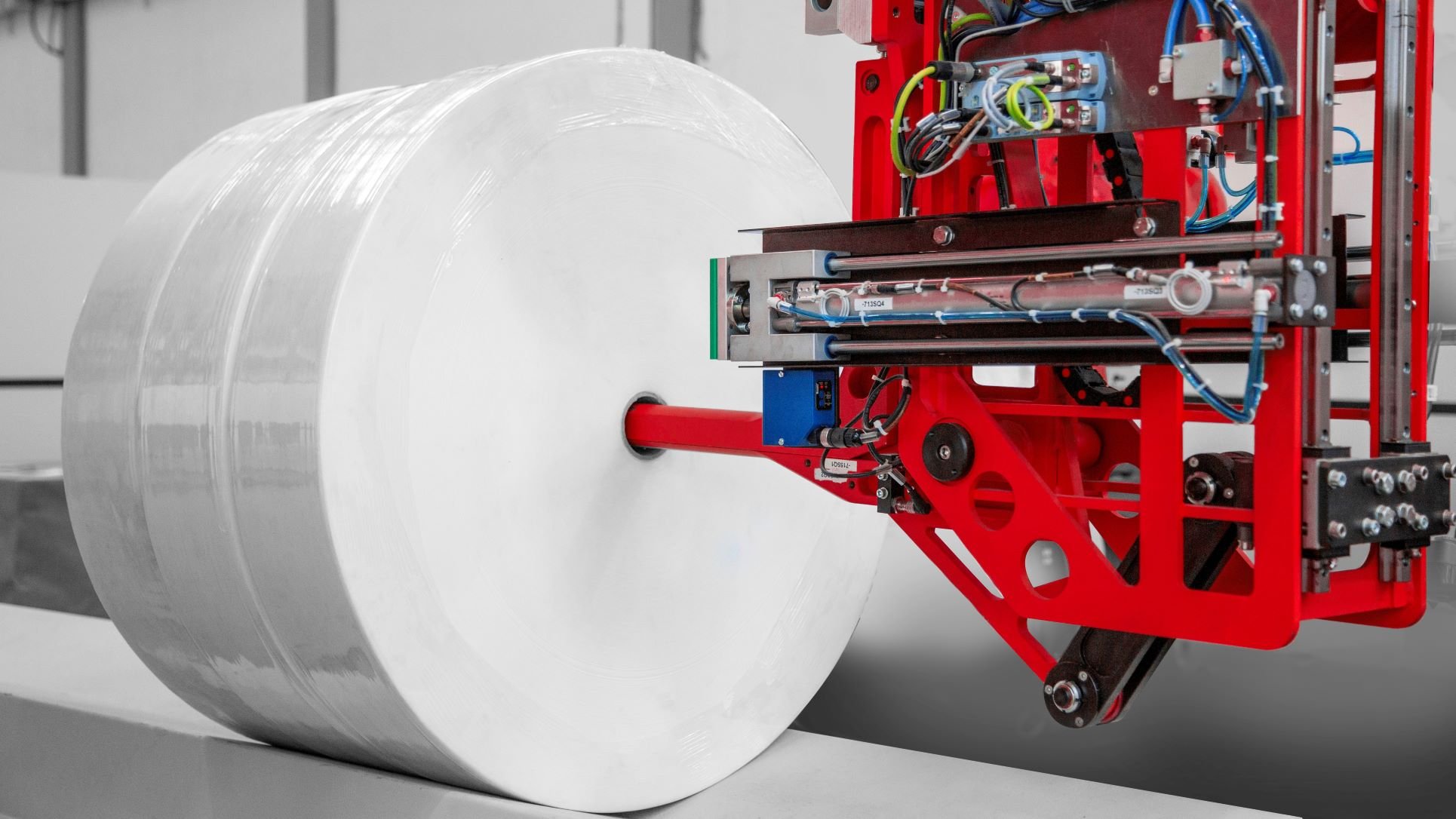

So let's see how, thanks to our solutions, it is possible both to carry out an automated packaging of nonwoven reels capable of preserving the quality of the material and to trace every single phase of the value creation process of the reel itself.

The delicate packaging phase

Once any lamination and printing phases have been completed, the nonwoven reels are ready for packaging. As we have previously mentioned, this phase can be critical for achieving the quality of the final product expected by our customers, as it is able to undermine the result obtained in previous processes.

For this reason, it is currently possible (and highly recommended) to implement automated systems capable of efficiently and effectively managing the entire packaging process.

In specific situations, even a single automatic packaging line can be used to process reels from multiple production lines. In this case, the reel handling operations towards the packaging line are performed automatically by means of transport systems capable of moving along tracks or through autonomous driving vehicles (AGV). Doing so not only prevents people from carrying out heavy and dangerous activities, but also eliminates the risk of any errors deriving from repetitive tasks that could lead to damage to the reels.

Automatic reel handling also reduces the possibility of another type of inconvenience arising: contamination, an event with particularly serious consequences for products intended for the medical sector and which leads to discard the reel.

If, on the other hand, the packaging line is integrated with a single production line, the automation of the process starts from the withdrawal of the nonwoven reels from the unloading table by means of a robot up to product packaging in accordance with to the requests of the specific customer, all using conveyor rollers with metal or Teflon-coated surfaces to move the reel during the various steps of the process.

The packaging can concern either single reels, if of considerable size, or a bundle, which is a stack of reels with smaller width and equal diameter. The automatic packaging operation can take place in three ways: horizontal, vertical and cocoon. It is also possibile to choose the number of external wraps and their tension to avoid damage to the material. In the case of bundles, these can be protected by means of a PE film and cardboard discs positioned on the top and bottom, while the edges can be coated with foam material.

To facilitate the transport of the bundle, it is possible to carry out a second packaging that secures the bundle itself to any pallet, however excluding any type of contact with the wood in order to avoid possible contamination.

How to certify the quality of the reels

The entire history of the reel is summarized in its label. For this reason, the labels applied both on the external surface of the reel and, often, on the core, are fundamental.

First, the label has a direct connection with the company ERP, allowing you to accurately verify all customer requests that the reel or bundle must comply with. By doing so, there is no danger of running into discussions or complaints for material that does not comply with the orders received. Secondly, the label contains all the information relating to each production phase of the reel thus providing complete traceability of the entire process. More specifically, through the label it is possible to trace:

- the quality controls carried out during all stages of production;

- the quality of the product and how this has possibly changed during the production phases;

- who followed the production of the reel and at what stage, being able to determine the reasons and responsibilities of any problems encountered on the final product.

Basically, the label is a certification of the quality of the finished product, which can also certify that the nonwoven reel intended for use in the medical field to which it refers does not appear to have come into contact with contaminants.

All this information can be obtained by scanning the barcode on the paper label or "reading" an RFID chip inside the same label. Usually the two techniques are used alternately, but it may happen that the same label offers both possibilities.

At the end of the whole process, weighing takes place, following which the consistency of the data on the label is checked with the data contained in the company ERP. If the finished product reflects the requests, the customer's management data is integrated with those relating to traceability created in the packaging process, thus being able to know the entire history of the reel.

Last but not least, A.Celli can offer an effective tracking system with dedicated management app based on RFID technology: the iREEL. This solution requires a label to be applied to the outer surface of the core to provide information on the composition of the packs and the reel IDs or to have details on any defects in the reel itself. iREEL can also be integrated with every solution for monitoring energy consumption, vibrations, alarms and machine status, as well as for the detection of technical data relating to the finished product.

A solution for all packaging needs: A.Celli R-WAY®

The distinguishing feature of an efficient automatic packaging system is the ability to adapt to individual business needs: that is, it must be versatile and customizable. It is in fact the ability to fit into each production line, integrating at best, which allows for optimal results.

These are the characteristics at the base of the A.Celli R-WAY® automatic packaging system, a modular, flexible and efficient solution able to cope with any workload, adaptable to any layout or production line and manageable by a single operator.

Having a customized automatic packaging system means having a system capable of operating at its best, without bottlenecks or inefficiencies. This is because there is an optimal management of workloads obtained thanks to a perfect concordance between production and packaging: both are calibrated on the same production volumes.

More in detail, the R-WAY® packaging system can automate all of the following operations (or, if necessary, only some of them), limiting the possibility of human error and contamination of the reels as much as possible:

- Transfer of the reel from the production line

- Packaging of finished rolls

- Reels and cores labeling

- Bundles labeling

- Weighing of the reel and bundles

- Vertical, horizontal or coocon packaging

- Possible palletization and second packaging

To achieve maximum process efficiency, the best possible quality of the final product and trace each processing step, focusing on automatic packaging is an excellent choice. In fact, it means using the best solution available to ensure that the reel reaches the end customer exactly as it left the production line.

Do you want to find out more about the complete range of A.Celli solutions for the end of line? Download our free eBook “A.Celli end-of-line solutions for nonwovens production”!